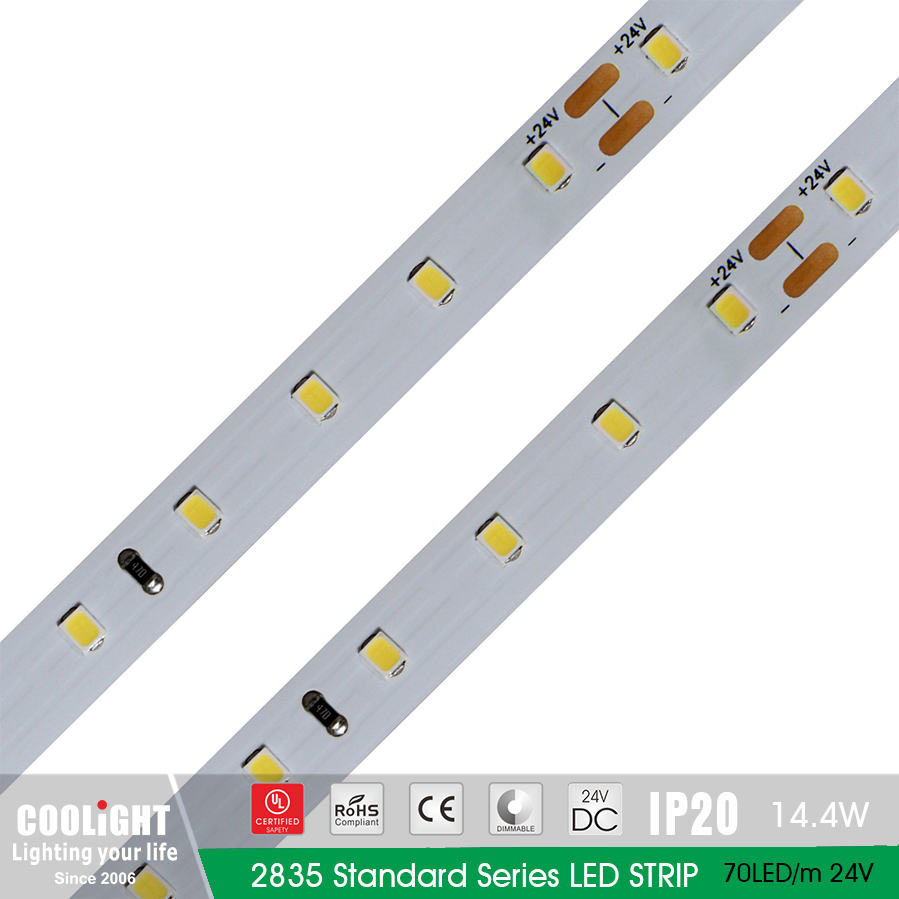

2835 70LED m 24V Standard Series LED STRIP

SEMIOFLEX J002 Static-White 24V 70LED meter CRI90 2835 IP68 Waterproof Flexible LED Strip

MOQ :1000 piece

Lead Time :10 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Credit Card,Western Union,Pay Pal

Product details

Product Specifications

- Brand name:LIMITED

- Input voltage:24v

- Light Source:LED

Product Description

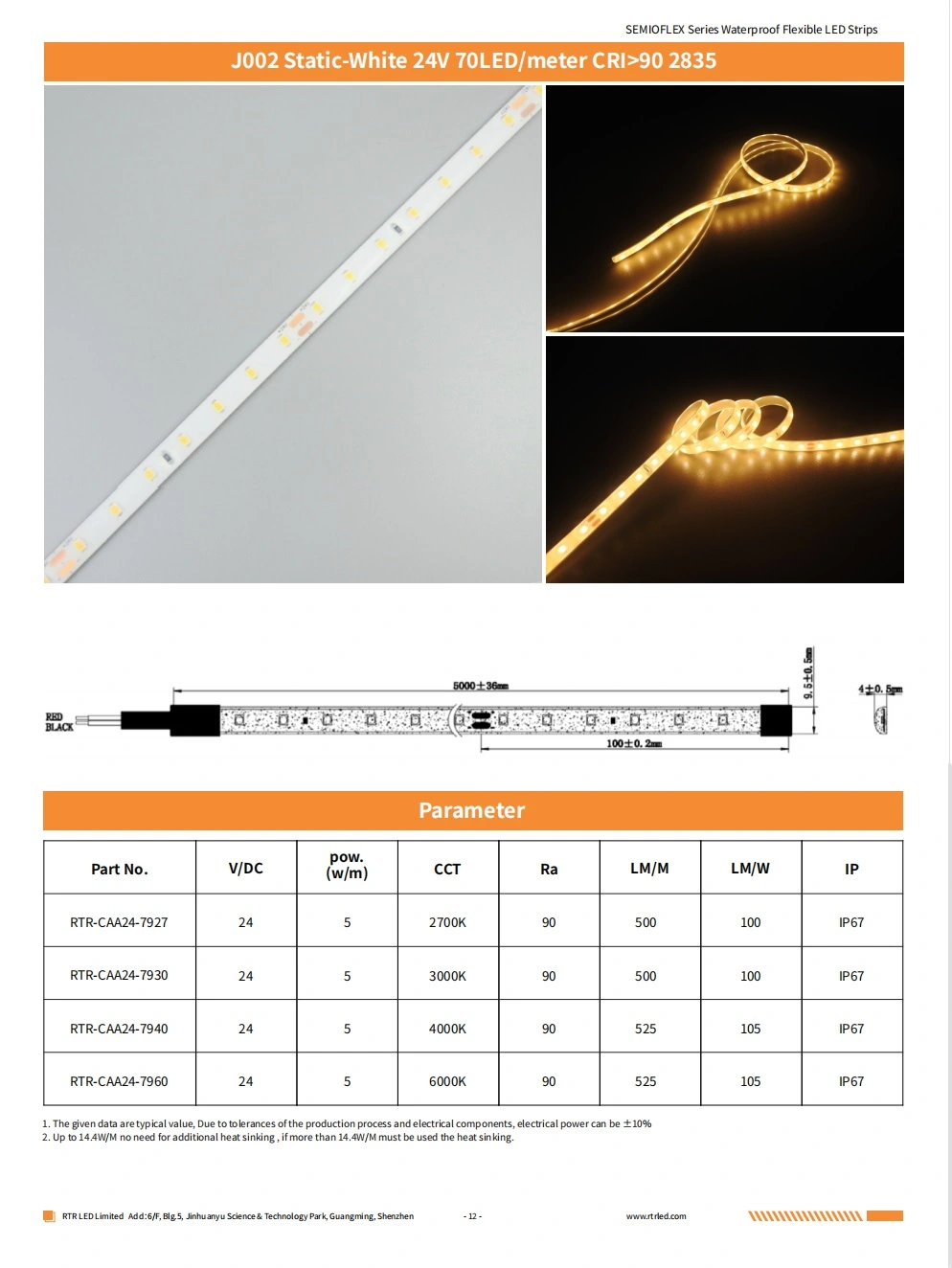

SEMIOFLEX J002 Static-White 24V 70LED/meter CRI>90 2835 IP68 Waterproof Flexible LED Strip

Totally warpped by silicone rubber, this product perform well in waterproof, dust proof, weather resistance, corrosion resistance. UV resistance, thermal conductivity. 70 LEDs a meter, low voltage, high IP rating and environmental friendly. High color rendering make the light high lumious. This strips can cut evey 10cm and a arc-shaped cross section allow it have a wide beam angle.

Parameter

| V/DC | 12V/24V/36V/48V | PCB Material | 2ounces Double Layer Copper FPC |

| POW. | 5W/9.6W/10W | PCB Width | 8mm |

| Light Color | White/Red/Yellow/Orange/Green/Blue/Cyan/Purple | Copper Width | 2oz |

| CCT | 2700K/3000K/4000K/6500K | Adhesive Tape | 3M VHB 300LSE |

| CRI | 90/95/97 | LED Chip Brand | San'an |

| Beam Angle | 120° | Storage Temperature | -35...+80oC |

| SDCM | 3 step | Ambient Temperature | -20...+45oC |

| IP Rating | IP68 | Waterproof Level | Waterproof |

| Cutting Unit(mm) | 50mm/100mm | Certification | CE RoHS |

| Warranty | 5 years | Photobiological Safety | IEC 62471 |

| SMD LED Source | 60/70/140leds/meter | Ingress Protection | EN 60529 |

| COB LED Source | 480leds/meter | Safety Requirement | EN 62031 IEC 60598-1 |

| Package | 5 meter/reel | EMC/Radio Disturbance Characteristics | EN 55015 |

Features & Detailed Photos

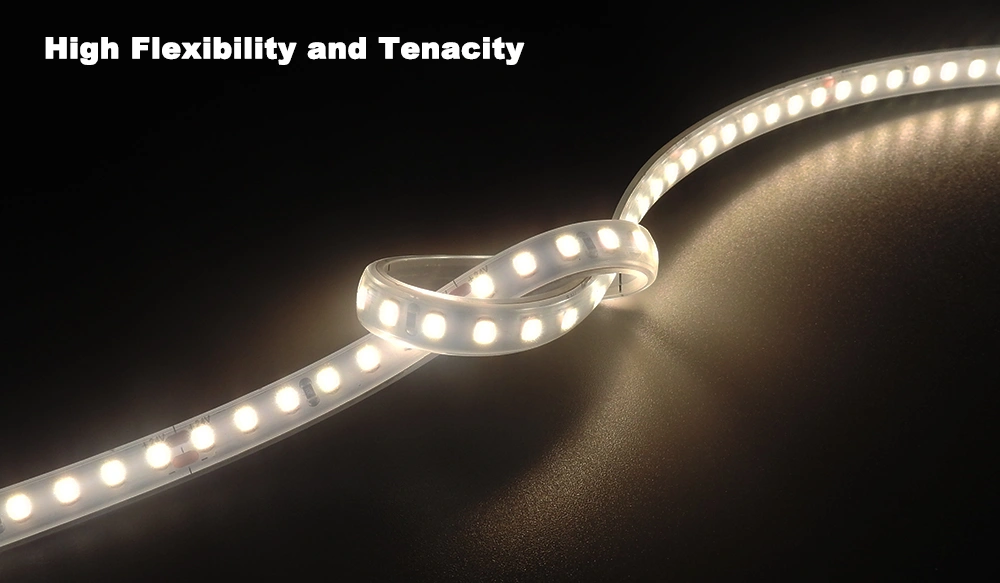

Flexibility

When we do interior decoration design, we often use the LED strip to make a variety of shapes. Our neon flex led strip use silicone compounds, molecular chain flexibility, weak interaction force, soft and elastic, with excellent heat aging resistance ultraviolet and ozone erosion, the use of integrated extrusion technology can make silicone and lamp perfect combination, the luminescence effect is not affected.

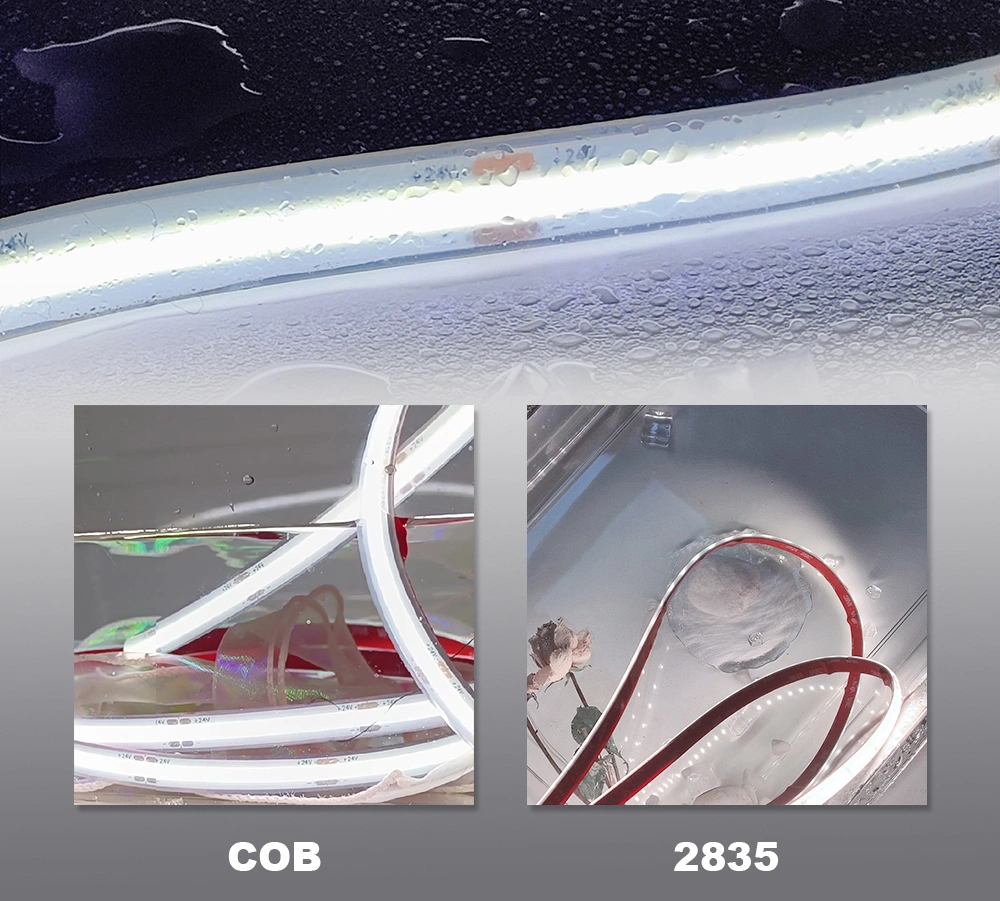

High IP Rating(IP68)

Our SEMIOFLEX Series Static-White Flexible LED strip adopts silicone integrated extrusion technology. Silicone extrusion means that the light bar will be extruded with the silicone at the same time. The light bar is fully wrapped by the silicone, which ensures that its waterproof and dustproof performance is similar and even better than traditional light strips with aluminum profiles.The protection level can reach IP68, also increasing the lifespan. It can be used in outdoor or indoor lavatory.

Easy to Cut and Install

Flexible PCB plus 3M adhesive backing tape make the strip light easy to cut and install. Every 5mm can be found a cut marks. And low voltage keeps the led strips safe to touch.

Different Color Options

Mix the different phosphor with silicone rubber in different proportions to make the COB led strips light in different colors. And there are 480 chips per meter arrange closely on the PCB so as to achieve the colorful light.

Connection

Our LED light strip can be cut as other COB LED Strip Light, and it is also easy to be connected. That ensures you could cut its length arbitrarily as your need. If you want to connect them again by yourself, you just need to prepare three things: a fast connector, a plier and a scissor.

Package & Shipment

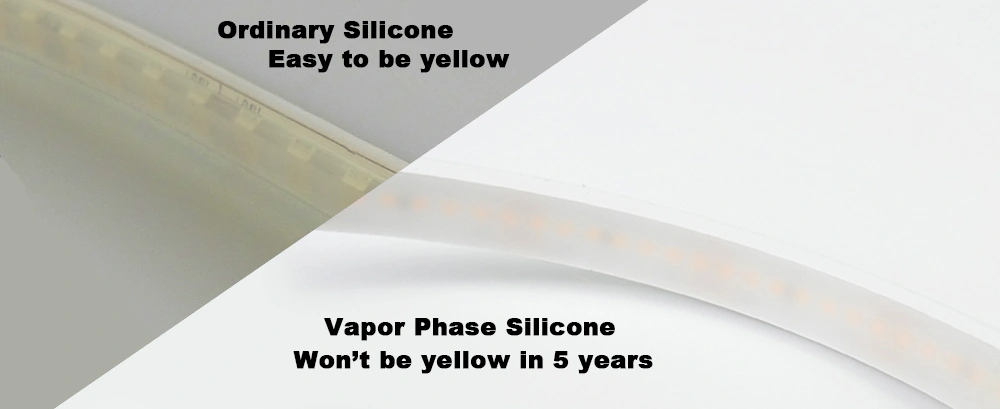

High Quality Silicone Rubber Without Yellowing

The light strip is fully-wrapped by food grade silicone material which is more flexible and has higher waterproof effect, better resistance to weather and corrosion, more prominent anti-UV ability than traditional PVC jacket. It can be used in outdoor environment. It could be exposed to direct sunlight for a long time, but will not be yellowing and aging.

Color Rendering Index

The color rendering ability of a light source to an object is called color rendering index, which is compared with the appearance color of the object with the reference or reference light source (incandescent light or drawing light).

Generally speaking, the highest color rendering index is 100. Above 90 is excellent, 80 is good, and below 60 is bad.

It is worth mentioning that the color rendering index of our light strips can reach CRI 97, which is a very good range. We have been committed to providing the best quality light strips.

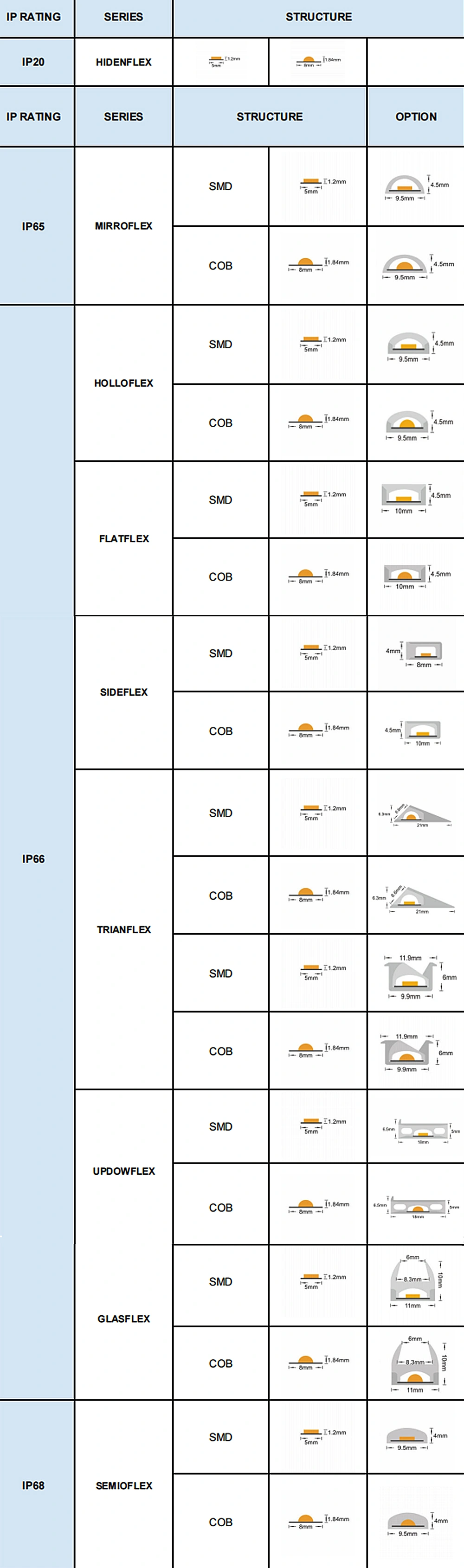

Strong Selectivity

IP20 led strip light can be extruded together with vapor phase silicone rubber. In addition to retaining its original characteristics, the protection level of the light strip has been improved a lot. Also, led light strip will change the beam angle after co-extruding with silicone rubber.

Technology

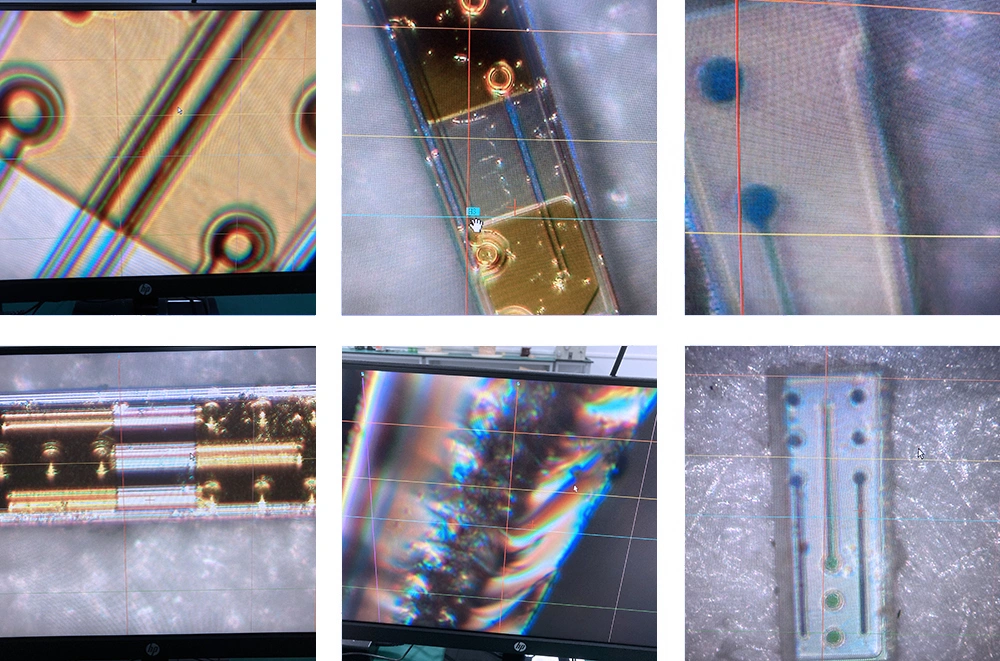

COB is the abbreviation of chip on board, which means the chip on board packaging technology. It is directly package multiple LED chips on the circuit board.

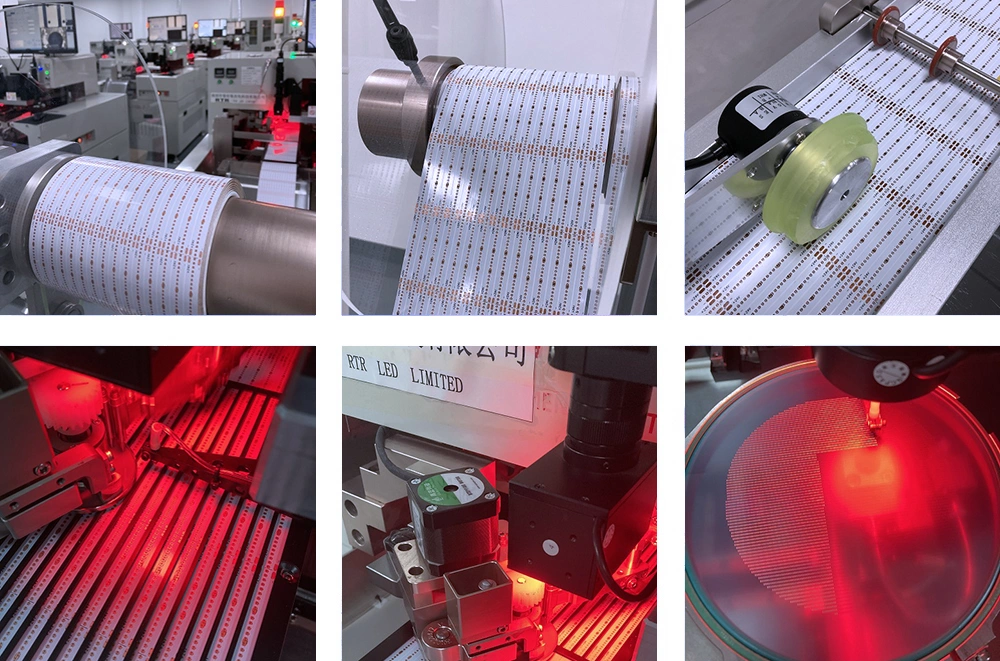

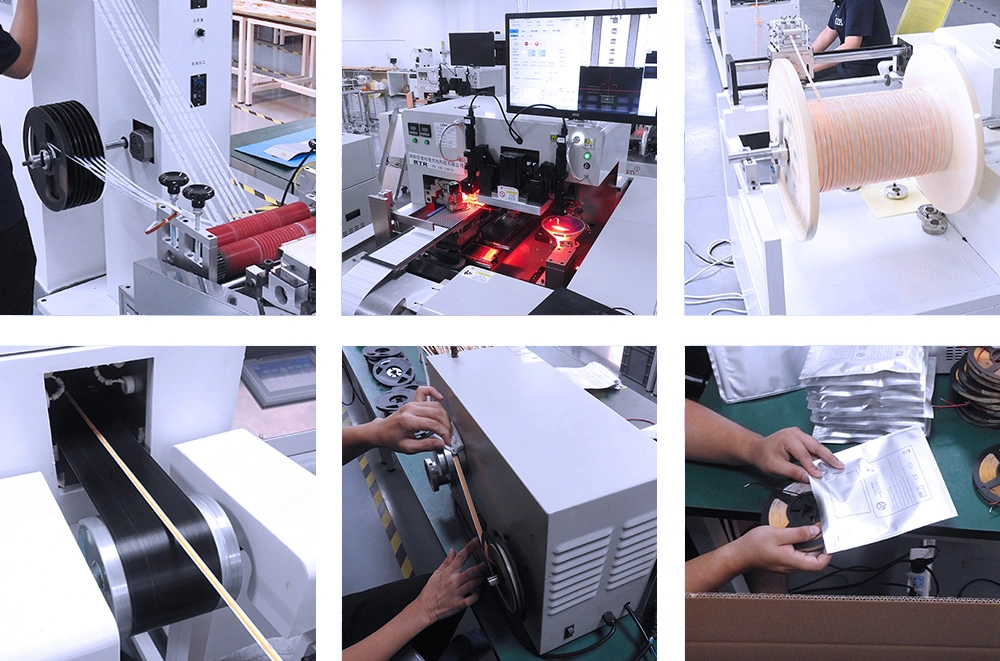

RTR LED Limited uses automatic COB LED Strip Light machine produce our products and achieve high production efficiency. We can manufacture thousands of meters of COB LED strip light a day. The steps of its manufacturing process are as follow: expanding chips, die-bonding-automated die attached process, resistors assemble, making silicone extrusion LED phosphor coating on the PCB, after extruding do the QC-Testing for the COB LED Strip Light on the color and lighting, soldering the PCB into the lengths for your requirements. When the products 100% pass the QC-Testing, it will be packaged and send to our customers all around the world.

The silicone extrusion molding process is a very complex technology. At a certain low temperature, adopting extrusion molding method to dissolve the silicone rubber. And then the dissolved silicone rubber will be sent to extruded machine to mold in some specific shapes. This is a relatively complex technology, so it requires high to the technicians. But this technology is more efficient, and can also reduce the production cost of enterprises, which is worthy of wide application by industry enterprises.

After the silicone products are extruded by the extruded machine, they are suspended to achieve prevulcanization and rapid shaping through the high temperature curing channel, and then fully vulcanized through the drying channel, which solves the production and quality problems that the traditional silicone rubber extrusion curing process cannot solve. Silicone extrusion process can be used to produce silicone tube, silicone strip, special-shaped strip, foaming tube, etc.

Company Profile

RTR LED LIMITED applies the advanced RTR(R2R,Roll to Roll) processing technology and the experienced silicone co-extrusion technology to produce high quality flexible LED strip linear lighting products.

Roll to roll (R2R) is a family of manufacturing technologies that provide continuous processing of a flexible substrate transferred between 2 moving rolls of material. It is an advanced manufacturing technology comparing to traditional other methods like sheet to sheet, sheets on shuttle and roll to sheet, and today roll to roll processing is applied in many manufacturing fields such as flexible electronics device, flexible solar panels, flexible printed circuit film, flexible thin film batteries etc.

In RTR company, we use it to produce high quality flexible LED strip linear lighting products. Our roll to roll manufacturing flexible LED strip lighting products based on roll to roll FPC manufacturing technology, flip chip LED chip die manufacturing technology and many roll to roll processing control technologies, and in our factory, we apply roll to roll continuous SMT machines, roll to roll die assembly machines, roll to roll AOI (Automatic Optical Inspection) machines, roll to roll flexible PCBA splitting machines, roll to roll phosphor glue coating machines, and roll to roll silicone extrusion production lines to produce our COB and SMD LED strip flex light products.

Certifications

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer,Service,Trading Company,Organization,Exporter,Importer,Wholesaler,Distributor,Agent,Retailer,Sourcing Office,Contractor,Chain Store

Company Location: GUANG DONG

Year Established: 3YRS

You May Like

-

2835 70LED m 24V Standard Series LED STRIP

-

2835 140LED m 24V Standard Series LED STRIP

-

2216 280LED m 24V LED STRIP

-

IP67 Silicon Glue Extrusion With Glue Inside

-

4X8mm Side View Neon Light

-

6.5X11mm Side View Neon Light

-

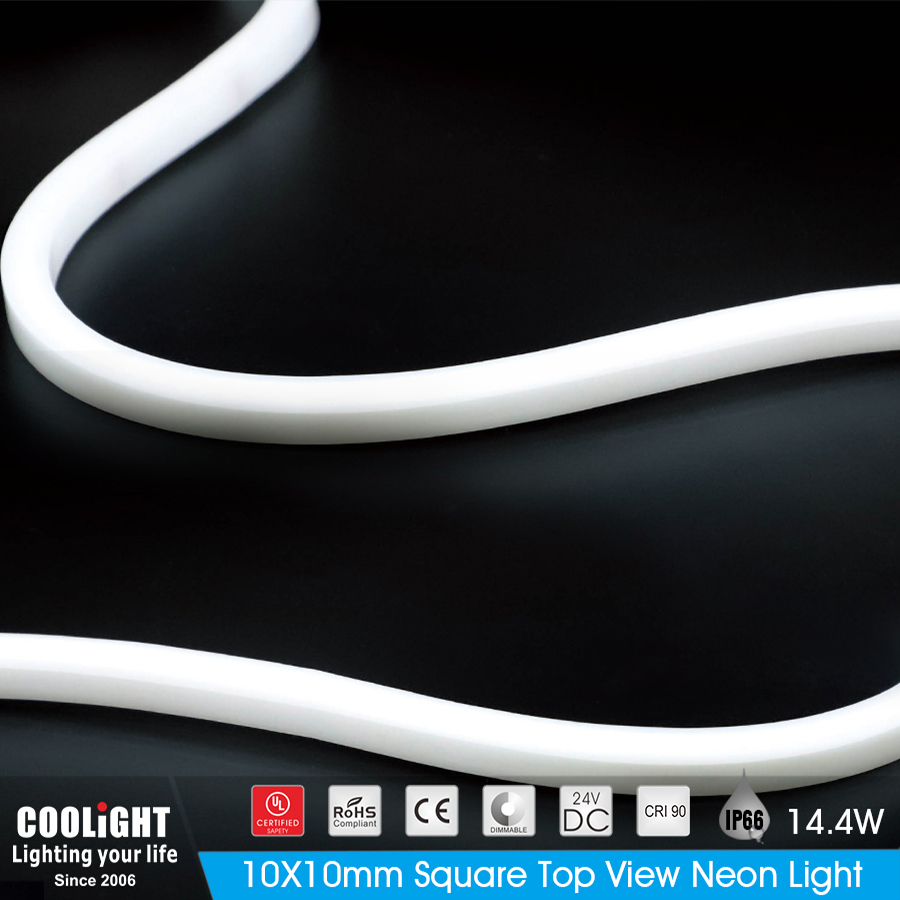

10X10mm Curve Top View Neon Light

-

10X10mm Square Top View Neon Light

-

COB 512 LED m 24V LED STRIPS

-

280LED 6mm PCB 24V Milky Dotless LED Strip